MetaPro can help customers to cut costs, prevent wasting time, and speed up work. Besides, we can share information with customers through our own production control system and quickly respond to unforeseen circumstances, making it easier for customers to come up with a short-time and long-term vision.

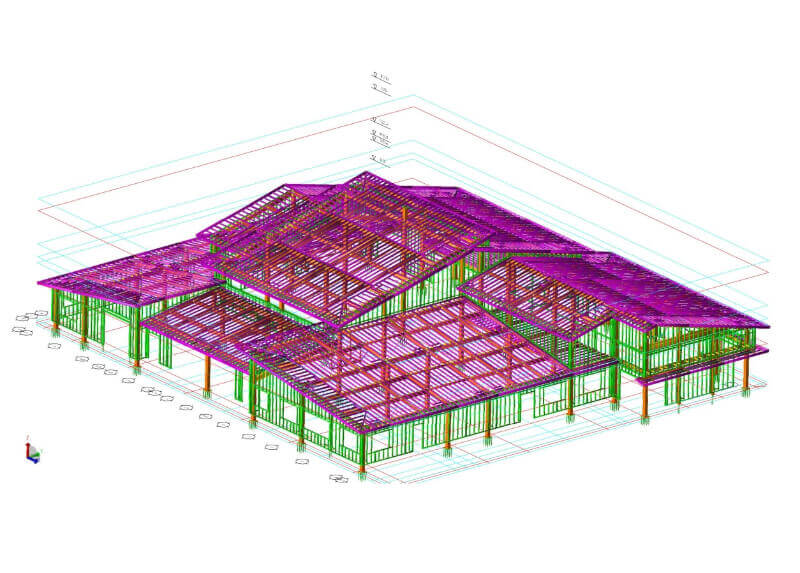

Construction Drawings

CAD System

Using the CAD system "REAL4" designed for steel frames, we input data and create drawings. We endeavor to prepare ourselves for sudden orders at any time and aims to be a company that can be chosen by customers.

CAM System (NC process data creation)

Hole drilling, Cutting, Marking (machine tools)

We can perform the positioning marking that has realized the number matching printing and non-scalability, which makes the hand-writing process unnecessary.

Assembly Process

Welding Process

Our qualified persons for each area handle the welding process. Keeping in mind the risks of erecting steel frames at construction sites, we process and manufacture products according to customers' instructions and "plus alpha."

Painting Process

Nationally certified painting technicians (*), which are rare in the architectural steel frame area. We endeavor to perform "professional work," not just "to paint beautifully!"

*Architecture/Steel Bridge Painting 1st Grade and 2nd Grade technicians.

Packing (according to each construction section/direction) / Sorting / Shipping

For smooth work at construction sites, we sort out packing in an easy-to-understand manner and thoroughly share information with customers and construction sites. We manage shipping by taking great care of it from a small lot to a large project.